Markets

Aviation

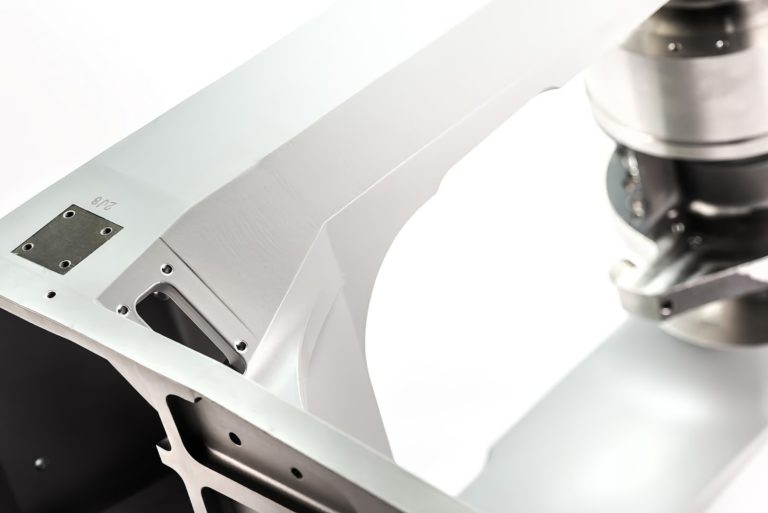

For years, LIDIO POIAN has been a partner of companies operating in the civil aeronautical and defense sector, manufacturing aircraft structural components, linkages, brackets, avionic boxes and prototypes.

Aerospace

Always at the forefront of design, the company has specialized in the machining of spacecrafts components. LIDIO POIAN manufactured prototypes and flight hardware for the drill subsystem for the rover of the ESA mission ExoMars 2022.

The space mission

Europe is about to set foot on Mars with the most sophisticated rover ever built. In short, this is the ExoMars mission, carried out by ESA in collaboration with the Russian space agency Roscosmos and with a very important contribution from Italy. It is a single project, carried out in two phases, with two different launches and with three different space probes.

Scientifically and technologically, this is a very ambitious challenge: find evidence of the existence of present or past life forms, by using a series of tools specifically designed. ESA has never achieved anything comparable in terms of complexity.

Military

The company is a longtime thrusted supplier for the production of parts for U.A.V. (Unmanned Aerial Vehicles), Eurofighter Typhoon, Tornado, radar systems, as well as parts for maintenance and upgrade for B707 Awacs and C130 aircrafts.

Civil

In the civil field, the company participates to conversion of passenger aircraft into cargo and provides support for their maintenance. Furthermore, LIDIO POIAN also collaborates with other companies in the production of components and subsystems for Airbus, Boeing and ATR, flexibly and promptly complying with the required deliveries.

Medical devices

Present for over thirty years in the medical sector for the supply of surgical instruments for implantology and prosthetic components for the shoulder, hip, knee and ankle joint, LIDIO POIAN stands out for its high level of surface finishes, for the precision of the couplings in the assembled components and for the ability to provide the customer with a finished product, treated, sterilized and marked, ready for use.

Diesel engines

LIDIO POIAN produce mechanical parts industrial diesel engines. These include valve bodies, flow indicators, fuel pumps, pistons, levers and various parts of shafts.

This work of great proportions also very high, require a great dimensional and geometrical precision. This collaboration has permitted the company to increase the knowledge of various materials e treatments including heat treatment and surface finish of the latest type and developing and applying these notions also in other fields.

Racing

The high level of technology of LIDIO POIAN’s production processes has led to cooperation with major brands in the motorsport and racing sector worldwide.

By working closely with racing departments, the company has been able to offer innovative and customized technical solutions, made with very high precision, which have allowed increased performance and greater longevity of the various products.

Thanks to this, in recent decades the components made by Lidio Poian have contributed to reaping success in the MotoGP, Superbike, Formula 1, Cross and Karting world championships.

Research

The search for new challenges has led LIDIO POIAN to become a partner of internationals research centers, with which it collaborates in the design and construction of measuring instruments, studying, in synergy with technicians and physicists, new research equipment.

The utmost attention for the details and the precision for geometrical and dimensional tolerances lead Lidio Poian to be one of the first companies to have produced a kit of spherical control tips characterized by millesimal tolerances, machined using unique equipment, designed and custom made by the company itself.

Furthermore, the company has been collaborating from the 80s with an important international group for the production of a laser micrometer, one of the most precise measuring instruments in the world, offering its own technical solutions for the production of mechanical components.

Furthermore, the company has been collaborating from the 80s with an important international group for the production of a laser micrometer, one of the most precise measuring instruments in the world, offering its own technical solutions for the production of mechanical components.

Plastic materials extrusion

Sixty years of experience in the field allows LIDIO POIAN to design and manufacture mechanical extrusion groupsets for plastic extrusion systems. Thanks to the technical attention and constructive care applied to the special extrusion heads developed, it is possible to improve the production capacity of plastic production industrial machinery and the quality of the final product.

General mechanics

With the experience gained in nearly eight decades of business, LIDIO POIAN also produces parts for the textile and food industry, equipment for the molds sector and for automotive industry. It reproduces, thanks to reverse engineering techniques, parts of machine tools and creates special tools of its own design, even with non-standard materials and treatments.